Cafta Fault Tree Software

A fault tree diagramFault tree analysis ( FTA) is a top-down, failure analysis in which an undesired state of a system is analyzed using to combine a series of lower-level events. This analysis method is mainly used in the fields of and to understand how systems can fail, to identify the best ways to reduce risk or to determine (or get a feeling for) event rates of a safety accident or a particular system level (functional) failure. FTA is used in the, and other high-hazard industries; but is also used in fields as diverse as risk factor identification relating to system failure. FTA is also used in software engineering for debugging purposes and is closely related to cause-elimination technique used to detect bugs.In aerospace, the more general term 'system failure condition' is used for the 'undesired state' / top event of the fault tree. These conditions are classified by the severity of their effects. The most severe conditions require the most extensive fault tree analysis.

These system failure conditions and their classification are often previously determined in the functional. Contents.Usage Fault tree analysis can be used to:. understand the logic leading to the top event / undesired state. show compliance with the (input) system safety / reliability requirements. prioritize the contributors leading to the top event- creating the critical equipment/parts/events lists for different importance measures. monitor and control the safety performance of the (e.g., is a particular aircraft safe to fly when fuel valve x malfunctions? For how long is it allowed to fly with the valve malfunction?).

minimize and optimize resources. assist in designing a system. The FTA can be used as a design tool that helps to create (output / lower level) requirements. function as a diagnostic tool to identify and correct causes of the top event. It can help with the creation of diagnostic manuals / processes.History Fault tree analysis (FTA) was originally developed in 1962 at by H.A. Watson, under a contract to evaluate the (ICBM) Launch Control System. The use of fault trees has since gained widespread support and is often used as a failure analysis tool by reliability experts.

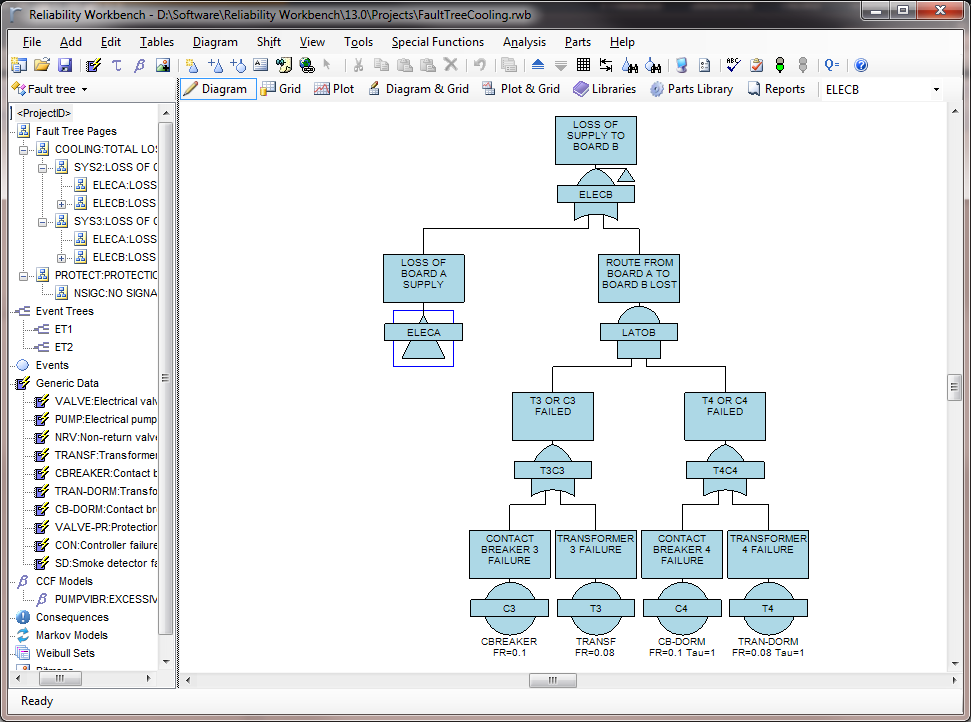

Describes the use of the Fault Tree Analysis Program (FTAP), an extensive computer package, written mostly in FORTRAN, which implements the Part I methodology. FTAP has a number of useful features that make it well-suited to nearly all fault tree applications. An input fault tree to this. The FaultTree+ in Reliability Workbench event tree analysis software module is unique in it’s ability to handle large scale problems and to fully handle success logic. The event tree model may be created independently of the fault tree model or may use fault tree analysis gate results as the source of event tree probabilities.

Following the first published use of FTA in the 1962 Minuteman I Launch Control Safety Study, and expanded use of FTA to the entire Minuteman II system in 1963-1964. FTA received extensive coverage at a 1965 Symposium in sponsored by Boeing and the. Boeing began using FTA for design around 1966.Subsequently, within the U.S. Military, application of FTA for use with fuzes was explored by in the 1960s and 1970s.

In 1976 the incorporated FTA into an Engineering Design Handbook on Design for Reliability. The Reliability Analysis Center at and its successor organizations now with the (Reliability Information Analysis Center, and now Defense Systems Information Analysis Center ) has published documents on FTA and reliability block diagrams since the 1960s. MIL-HDBK-338B provides a more recent reference.In 1970, the (FAA) published a change to regulations for in the at 35 FR 5665 (1970-04-08). This change adopted failure probability criteria for and equipment and led to widespread use of FTA in civil aviation.

In 1998, the FAA published Order 8040.4, establishing risk management policy including hazard analysis in a range of critical activities beyond aircraft certification, including and modernization of the U.S. This led to the publication of the FAA System Safety Handbook, which describes the use of FTA in various types of formal hazard analysis.Early in the the question was asked about the probability of successfully sending astronauts to the moon and returning them safely to Earth. A risk, or reliability, calculation of some sort was performed and the result was a mission success probability that was unacceptably low. This result discouraged NASA from further quantitative risk or reliability analysis until after the Challenger accident in 1986.

Instead, NASA decided to rely on the use of and other qualitative methods for system safety assessments. After the Challenger accident, the importance of (PRA) and FTA in systems risk and reliability analysis was realized and its use at NASA has begun to grow and now FTA is considered as one of the most important system reliability and safety analysis techniques.Within the nuclear power industry, the began using PRA methods including FTA in 1975, and significantly expanded PRA research following the 1979 incident at. This eventually led to the 1981 publication of the NRC Fault Tree Handbook NUREG–0492, and mandatory use of PRA under the NRC's regulatory authority.Following process industry disasters such as the 1984 and 1988 explosion, in 1992 the (OSHA) published in the Federal Register at 57 FR 6356 (1992-02-24) its (PSM) standard in 19 CFR 1910.119. OSHA PSM recognizes FTA as an acceptable method for (PHA).Today FTA is widely used in and, and in all major fields of engineering.Methodology FTA methodology is described in several industry and government standards, including NRC NUREG–0492 for the nuclear power industry, an aerospace-oriented revision to NUREG–0492 for use by, for civil aerospace, MIL–HDBK–338 for military systems, standard IEC 61025 is intended for cross-industry use and has been adopted as European Norm EN 61025.Any sufficiently complex system is subject to failure as a result of one or more subsystems failing. The likelihood of failure, however, can often be reduced through improved system design.

Cafta Fault Tree Analysis

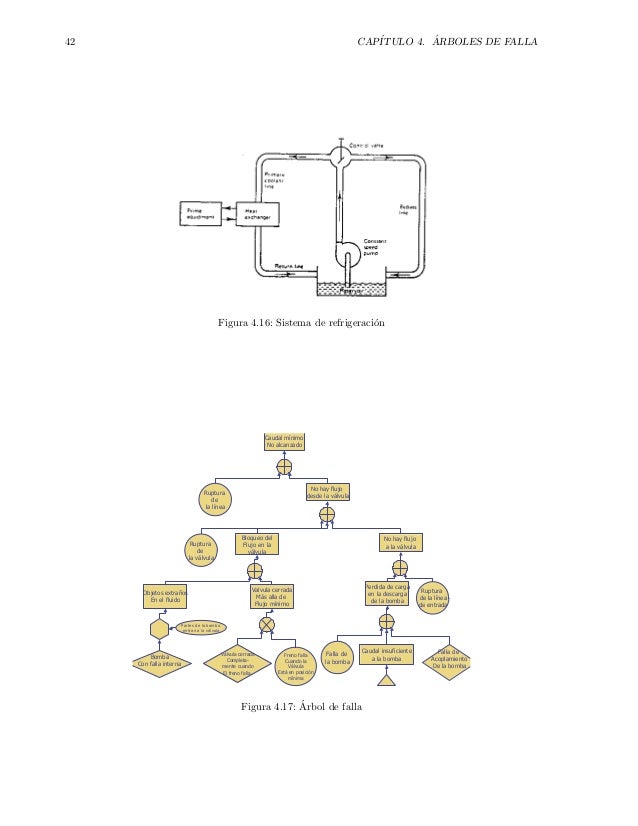

Fault tree analysis maps the relationship between faults, subsystems, and redundant safety design elements by creating a logic diagram of the overall system.The undesired outcome is taken as the root ('top event') of a tree of logic. For instance the undesired outcome of a metal stamping press operation is a human appendage being stamped. Working backward from this top event we might determine there are two ways this could happen: during normal operation or during maintenance operation. This condition is a logical OR.

Considering the branch of occurring during normal operation perhaps we determine there are two ways this could happen: the press cycles and harms the operator or the press cycles and harms another person. This is another logical OR.

We can make a design improvement by requiring the operator to press two buttons to cycle the machine—this is a safety feature in the form of a logical AND. The button may have an intrinsic failure rate—this becomes a fault stimulus we can analyze. When fault trees are labeled with actual numbers for failure probabilities, can calculate failure probabilities from fault trees.When a specific event is found to have more than one effect event, i.e. It has impact on several subsystems, it is called a common cause or common mode.

Graphically speaking, it means this event will appear at several locations in the tree. Common causes introduce dependency relations between events.

The probability computations of a tree which contains some common causes are much more complicated than regular trees where all events are considered as independent. Not all software tools available on the market provide such capability.The tree is usually written out using conventional symbols. A cut set is a combination of events, typically component failures, causing the top event.

If no event can be removed from a cut set without causing the top event, then it is called a minimal cut set.Some industries use both fault trees and (see ). An event tree starts from an undesired initiator (loss of critical supply, component failure etc.) and follows possible further system events through to a series of final consequences. As each new event is considered, a new node on the tree is added with a split of probabilities of taking either branch. The probabilities of a range of 'top events' arising from the initial event can then be seen.Classic programs include the 's (EPRI) CAFTA software, which is used by many of the US nuclear power plants and by a majority of US and international aerospace manufacturers, and the 's, which is used by the U.S. Government to evaluate the safety and of, the, and the. Outside the US, the software RiskSpectrum is a popular tool for fault tree and event tree analysis, and is licensed for use at almost half of the world's nuclear power plants for probabilistic safety assessment. Professional-grade is also widely available; SCRAM is an open-source tool that implements the Open-PSA Model Exchange Format open standard for probabilistic safety assessment applications.Graphic symbols The basic symbols used in FTA are grouped as events, gates, and transfer symbols.

Minor variations may be used in FTA software.Event symbols Event symbols are used for primary events and intermediate events. Primary events are not further developed on the fault tree. Intermediate events are found at the output of a gate. The event symbols are shown below:. Transfer outBasic mathematical foundation Events in a fault tree are associated with. For example, component failures may typically occur at some constant λ (a constant hazard function).

In this simplest case, failure probability depends on the rate λ and the exposure time t:P = 1 - exp(-λt) P ≈ λt, λt.

A fault tree diagramFault tree analysis ( FTA) is a top-down, failure analysis in which an undesired state of a system is analyzed using to combine a series of lower-level events. This analysis method is mainly used in the fields of and to understand how systems can fail, to identify the best ways to reduce risk or to determine (or get a feeling for) event rates of a safety accident or a particular system level (functional) failure. FTA is used in the, and other high-hazard industries; but is also used in fields as diverse as risk factor identification relating to system failure. FTA is also used in software engineering for debugging purposes and is closely related to cause-elimination technique used to detect bugs.In aerospace, the more general term 'system failure condition' is used for the 'undesired state' / top event of the fault tree. These conditions are classified by the severity of their effects. The most severe conditions require the most extensive fault tree analysis. These system failure conditions and their classification are often previously determined in the functional.

Contents.Usage Fault tree analysis can be used to:. understand the logic leading to the top event / undesired state. show compliance with the (input) system safety / reliability requirements. prioritize the contributors leading to the top event- creating the critical equipment/parts/events lists for different importance measures. monitor and control the safety performance of the (e.g., is a particular aircraft safe to fly when fuel valve x malfunctions?

For how long is it allowed to fly with the valve malfunction?). minimize and optimize resources. assist in designing a system. The FTA can be used as a design tool that helps to create (output / lower level) requirements. function as a diagnostic tool to identify and correct causes of the top event. It can help with the creation of diagnostic manuals / processes.History Fault tree analysis (FTA) was originally developed in 1962 at by H.A.

Watson, under a contract to evaluate the (ICBM) Launch Control System. The use of fault trees has since gained widespread support and is often used as a failure analysis tool by reliability experts.

Following the first published use of FTA in the 1962 Minuteman I Launch Control Safety Study, and expanded use of FTA to the entire Minuteman II system in 1963-1964. FTA received extensive coverage at a 1965 Symposium in sponsored by Boeing and the. Boeing began using FTA for design around 1966.Subsequently, within the U.S.

Military, application of FTA for use with fuzes was explored by in the 1960s and 1970s. In 1976 the incorporated FTA into an Engineering Design Handbook on Design for Reliability. The Reliability Analysis Center at and its successor organizations now with the (Reliability Information Analysis Center, and now Defense Systems Information Analysis Center ) has published documents on FTA and reliability block diagrams since the 1960s. MIL-HDBK-338B provides a more recent reference.In 1970, the (FAA) published a change to regulations for in the at 35 FR 5665 (1970-04-08).

This change adopted failure probability criteria for and equipment and led to widespread use of FTA in civil aviation. In 1998, the FAA published Order 8040.4, establishing risk management policy including hazard analysis in a range of critical activities beyond aircraft certification, including and modernization of the U.S. This led to the publication of the FAA System Safety Handbook, which describes the use of FTA in various types of formal hazard analysis.Early in the the question was asked about the probability of successfully sending astronauts to the moon and returning them safely to Earth. A risk, or reliability, calculation of some sort was performed and the result was a mission success probability that was unacceptably low. This result discouraged NASA from further quantitative risk or reliability analysis until after the Challenger accident in 1986.

Instead, NASA decided to rely on the use of and other qualitative methods for system safety assessments. After the Challenger accident, the importance of (PRA) and FTA in systems risk and reliability analysis was realized and its use at NASA has begun to grow and now FTA is considered as one of the most important system reliability and safety analysis techniques.Within the nuclear power industry, the began using PRA methods including FTA in 1975, and significantly expanded PRA research following the 1979 incident at. This eventually led to the 1981 publication of the NRC Fault Tree Handbook NUREG–0492, and mandatory use of PRA under the NRC's regulatory authority.Following process industry disasters such as the 1984 and 1988 explosion, in 1992 the (OSHA) published in the Federal Register at 57 FR 6356 (1992-02-24) its (PSM) standard in 19 CFR 1910.119. OSHA PSM recognizes FTA as an acceptable method for (PHA).Today FTA is widely used in and, and in all major fields of engineering.Methodology FTA methodology is described in several industry and government standards, including NRC NUREG–0492 for the nuclear power industry, an aerospace-oriented revision to NUREG–0492 for use by, for civil aerospace, MIL–HDBK–338 for military systems, standard IEC 61025 is intended for cross-industry use and has been adopted as European Norm EN 61025.Any sufficiently complex system is subject to failure as a result of one or more subsystems failing. The likelihood of failure, however, can often be reduced through improved system design. Fault tree analysis maps the relationship between faults, subsystems, and redundant safety design elements by creating a logic diagram of the overall system.The undesired outcome is taken as the root ('top event') of a tree of logic.

For instance the undesired outcome of a metal stamping press operation is a human appendage being stamped. Working backward from this top event we might determine there are two ways this could happen: during normal operation or during maintenance operation. This condition is a logical OR.

Considering the branch of occurring during normal operation perhaps we determine there are two ways this could happen: the press cycles and harms the operator or the press cycles and harms another person. This is another logical OR. We can make a design improvement by requiring the operator to press two buttons to cycle the machine—this is a safety feature in the form of a logical AND.

The button may have an intrinsic failure rate—this becomes a fault stimulus we can analyze. When fault trees are labeled with actual numbers for failure probabilities, can calculate failure probabilities from fault trees.When a specific event is found to have more than one effect event, i.e. It has impact on several subsystems, it is called a common cause or common mode. Graphically speaking, it means this event will appear at several locations in the tree.

Common causes introduce dependency relations between events. The probability computations of a tree which contains some common causes are much more complicated than regular trees where all events are considered as independent. Not all software tools available on the market provide such capability.The tree is usually written out using conventional symbols. A cut set is a combination of events, typically component failures, causing the top event. If no event can be removed from a cut set without causing the top event, then it is called a minimal cut set.Some industries use both fault trees and (see ).

An event tree starts from an undesired initiator (loss of critical supply, component failure etc.) and follows possible further system events through to a series of final consequences. As each new event is considered, a new node on the tree is added with a split of probabilities of taking either branch.

The probabilities of a range of 'top events' arising from the initial event can then be seen.Classic programs include the 's (EPRI) CAFTA software, which is used by many of the US nuclear power plants and by a majority of US and international aerospace manufacturers, and the 's, which is used by the U.S. Government to evaluate the safety and of, the, and the. Outside the US, the software RiskSpectrum is a popular tool for fault tree and event tree analysis, and is licensed for use at almost half of the world's nuclear power plants for probabilistic safety assessment. Professional-grade is also widely available; SCRAM is an open-source tool that implements the Open-PSA Model Exchange Format open standard for probabilistic safety assessment applications.Graphic symbols The basic symbols used in FTA are grouped as events, gates, and transfer symbols. Minor variations may be used in FTA software.Event symbols Event symbols are used for primary events and intermediate events.

Primary events are not further developed on the fault tree. Intermediate events are found at the output of a gate. The event symbols are shown below:.

Transfer outBasic mathematical foundation Events in a fault tree are associated with. For example, component failures may typically occur at some constant λ (a constant hazard function). In this simplest case, failure probability depends on the rate λ and the exposure time t:P = 1 - exp(-λt) P ≈ λt, λt.